Home > Rene 41 Bar

Expertly designed to meet the stringent demands of a range of industrial products, our Rene 41 Bar stands out for its unique quality. Precisely tailored to meet the industry’s exacting industry standards, these tapes offer exceptional thermal expansion characteristics, superior mechanical strength and outstanding durability in demanding environments We are committed to exceeding customers expectations by providing tailor-made solutions where longevity and reliable performance are required. Increase your productivity with our Rene 41 Bar backed by our unwavering commitment to exceptional craftsmanship.

| Standards : | AMS 5545, AMS 5712, AMS 5713, AMS 5800, EN 2.4973, GE B50T59, GE B50TF109, GE B50TF76, UNS N07041, Werkstoff 2.4973 |

| Thickness : | Range from .008″ to .0125″ |

| Hardness : | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Form : | Round Bar, Wire |

| Tungsten Grades | HA 190 / HA 1925 / HA 195 / HE 390 / HE 3925 / HE 395 / HE 397 |

| Cr | Ni | Mo | Co | Al | Ti | B | C | Fe | Mn | Si | S | Cu | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MIN | 18.00 | — | 9.00 | 10.00 | 1.40 | 3.00 | 0.003 | — | — | — | — | — | — |

| MAX | 20.00 | Balance | 10.50 | 12.00 | 1.80 | 3.30 | 0.01 | 0.12 | 5.00 | 0.10 | 0.50 | 0.015 | 0.50 |

| Mechanical & Physical Properties | 21°C | 427°C | 538°C | 649°C | 760°C | 871°C | 982°C |

|---|---|---|---|---|---|---|---|

| Ultimate Tensile Strength /MPa | 1261.7 | – | – | 1117 | 1048 | 710.2 | – |

| 0.2% Yield Strength /MPa | 820.5 | – | – | 765.3 | 751.5 | 579.2 | – |

| Elongation % | 21 | – | – | 14 | 14 | 11 | – |

| Coefficient of Thermal Expansion µm/m⁰C | – | 13.3 | 13.7 | 14.3 | 15.1 | 15.5 | 16.7 |

| Thermal Conductivity /kcal/(hr.m.°C) | – | 14.4 | 16.1 | 17.9 | 19.6 | 21.4 | – |

| Modulus of Elasticity / x105 MPa | – | 2 | 1.93 | 1.79 | 1.72 | 1.65 | 1.52 |

At PipingMart, we take pride in being the largest supplier and manufacturer in the UAE, offering cutting-edge solutions for all your piping needs. With state-of-the-art production plants strategically located in the UAE, we boast a vast inventory of over 25,000 tons of premium-quality materials readily available in stock.

Contact us to get a quick quote for your requirement.

We offer These Rene 41 Bar as per DIN, ISO, JIS or ANSI Standard.

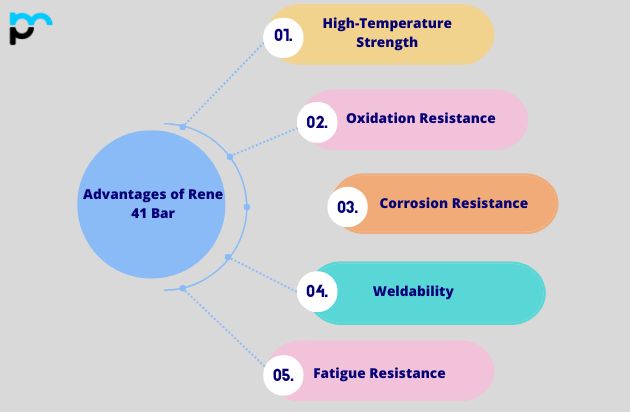

Due to their exceptional properties, Rene 41 Bar are essential components across many industrial sectors. Renowned for their corrosion resistance, they find widespread application in marine environments, enduring the rigours of saltwater exposure with longevity and reliability. In the construction industry, stainless steel fasteners play a pivotal role in structural assemblies, providing secure connections while maintaining structural integrity in outdoor and exposed settings.

Yes, a Kovar bar can be reused after use. Kovar is an alloy made primarily of iron, nickel and cobalt that is known for its very broad thermal conductivity, making it ideal for coating glass in metals When recycled, Kovar retains its useful properties of the material, allowing it to be reused in other products. Kovar recycling reduces the amount of raw materials needed, making it an environmentally friendly option. However, the recycling process must be done carefully to ensure the integrity and functionality of the compound.